Wolfram Carbide--Wolfram Carbide Bar

What exactly is Wolfram Carbide?

At its core, it is a composite material made from tungsten carbide particles embedded in a matrix of metallic cobalt. This unique combination results in a material that is harder than steel and can withstand extreme conditions, making it ideal for high-temperature applications, cutting tools, and wear-resistant parts.

Wolfram Carbide's exceptional properties are transforming various industries, from aerospace and automotive to oil and gas. Its hardness and resistance to wear and corrosion are enhancing the performance and lifespan of critical components, reducing maintenance costs, and improving overall efficiency.

Advantages of Wolfram Carbide in manufacturing

Wolfram Carbide has excellent thermal stability, making it suitable for high-temperature applications. This property enables manufacturers to use the material in harsh environments where other materials may fail. Additionally, its corrosion resistance ensures that products made with Wolfram Carbide remain unaffected by harsh chemicals or corrosive substances.

Wolfram Carbide offers superior strength, allowing manufacturers to create products with thinner and lighter profiles without compromising on durability. This not only reduces material costs but also improves the overall performance of the products. The material's high compressive strength also makes it ideal for use in cutting tools, where it can withstand the tremendous forces exerted during machining operations.

Comparing Wolfram Carbide with other materials

Wolfram Carbide Compared to titanium, Wolfram Carbide offers superior hardness and wear resistance. While titanium is lightweight and has excellent corrosion resistance, it lacks the hardness necessary for many manufacturing applications. Wolfram Carbide's exceptional hardness makes it a preferable choice for industries that require durable and wear-resistant materials.

Ceramic materials, on the other hand, offer excellent hardness and wear resistance but are prone to cracking and brittleness. Wolfram Carbide, with its combination of tungsten carbide particles and metallic cobalt matrix, provides a more robust and reliable solution for manufacturing applications. It offers the hardness and wear resistance of ceramics without the brittleness.

Furthermore, Wolfram Carbide's exceptional thermal stability sets it apart from other materials. While steel and titanium may deform or lose their mechanical properties at high temperatures, Wolfram Carbide remains stable and can withstand extreme heat. This property makes it suitable for high-temperature applications where other materials would fail.

While Wolfram Carbide offers numerous advantages in manufacturing applications, it is important to consider the cost implications of using this material. Wolfram Carbide tools and components may have a higher upfront cost compared to those made from conventional materials like steel. However, when considering the long-term benefits and cost savings, Wolfram Carbide often proves to be a cost-effective choice.

One major cost-saving aspect of Wolfram Carbide is its exceptional durability and wear resistance. Products made from Wolfram Carbide last significantly longer than those made from other materials, reducing the need for frequent replacements. This not only saves on material costs but also reduces downtime and maintenance expenses, resulting in overall cost savings for manufacturers.

Grade Of Carbide Wear Strips

Grade WC+others Co Grain Size (μm) Hardness (HV30) Hardness (HRV) TRS (N/mm²) sample C TRS (KPSI) Density(g/cc)

TM108 92% 8% 0.2 2100 94.6 4500 652.5 14.46

TMU30 88% 12% 0.4 1750 92.5 4000 580 14.1

TM06 94% 6% 0.6 1850 93.1 3600 522 14.9

TM20T 90% 10% 0.6 1650 91.7 3800 551 14.45

TM30 88% 12% 0.6 1700 92.3 4000 580 14.1

TM10.2 90% 10% 0.8 1600 91.5 4000 580 14.42

TM10A 92% 8% 0.8 1780 92.8 3800 551 14.65

TM209 91% 9% 0.2 2050 94.2 4800 656 14.36

TM20C 92% 8% 0.8 2020 93.6 5000 663 14.58

TM208 92% 8% 0.2 2150 95 4700 651 14.5

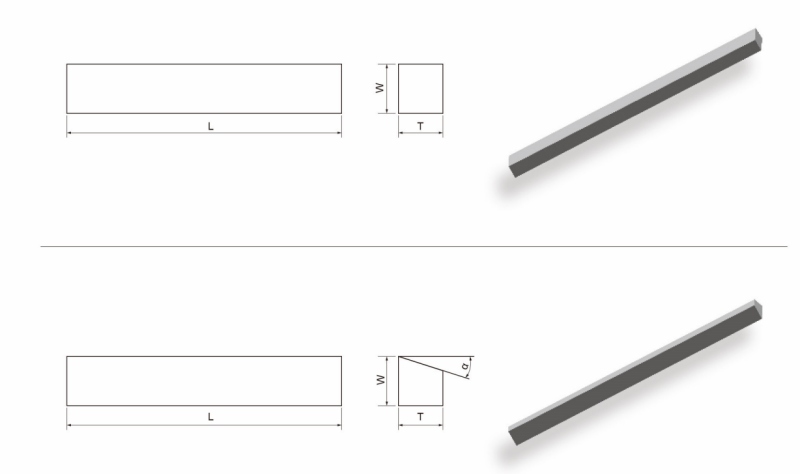

Sizes Of Tungsten Carbide Strips

Type Size Range Tolerance

T(mm) 1.0<T<16.0 (+0.1,+0.5)

W (mm) 1.0<W<32.0 (+0.1,+0.5)

L (mm) 260<L<700 (+0.0,+0.8)

α (°) 0-35° (±1°)

For further information (MOQ, price, delivery, etc), please request a quote or send us an email at [email protected]. Our sales team and engineers are ready to offer their expertise

Wolfram Carbide Bar

- Product Code: wcb001

- Availability: In Stock

Related Products

Carbide Wear Strips

Carbide Wear StripsCarbide wear strips are becoming increasingly popular in industries that demand r..

Tags: Wolfram Carbide, tungsten and carbide, tungsten carbide metal, tungsten carbide bar