Tungsten Carbide For Oil & Gas Industry

Tungsten Carbide For Oil & Gas Industry

Tungsten carbide is a popular material used in the oil and gas industry due to its exceptional mechanical and physical properties. Here are some ways in which tungsten carbide is used in the industry:

- Drilling tools: Tungsten carbide is widely used in drilling tools such as drill bits and stabilizers. Tungsten carbide is a hard and wear-resistant material that can withstand harsh drilling conditions, including high temperatures, pressures, and abrasive materials.

- Wear parts: Tungsten carbide is used to make wear parts such as valve seats, flow control equipment, and pump plungers. These parts are exposed to erosive and corrosive materials, and tungsten carbide's hardness and resistance to wear make it an excellent choice for such applications.

- Corrosion-resistant coatings: Tungsten carbide coatings are used to protect oil and gas equipment from corrosion. The coating provides a hard and durable layer that can withstand the corrosive effects of harsh chemicals and gases.

In the oil and gas industry, wear parts are used in pumps, valves, flow control equipment, and other components that are exposed to abrasive and corrosive materials. Tungsten carbide is a popular material for wear parts due to its high hardness and wear resistance.

Tungsten carbide wear parts are manufactured using a process called powder metallurgy. In this process, tungsten carbide powder is mixed with a binder material, such as cobalt, and then pressed into the desired shape. The mixture is then sintered, a process that involves heating the part in a vacuum or controlled atmosphere to bond the tungsten carbide particles together and create a dense, hard material.

The resulting tungsten carbide wear parts have high resistance to wear and abrasion, making them suitable for use in harsh and demanding environments. Some common tungsten carbide wear parts used in the oil and gas industry include valve seats, plungers, bushings, and sleeves.

In addition to tungsten carbide, other materials such as ceramics, high-performance polymers, and advanced coatings can also be used to manufacture wear parts with high wear resistance and durability.

For further information (MOQ, price, delivery, etc), please request a quote or send us an email at [email protected]. Our sales team and engineers are ready to offer their expertise.

3/32 (2.381mm) Tungsten Carbide Balls

3/32 (2.381mm) Tungsten Carbide BallsWhat sizes of tungsten carbide balls does TUNGSTEN MAN provide?..

Buy Tungsten Alloy Ball From Manufacture--TUNGSTEN MAN

Buy Tungsten Alloy Ball From Manufacture--TUNGSTEN MANAre you in need of high-quality tungsten alloy..

Buy Tungsten Balls From TUNGSTEN MAN

Shaping Perfection: Buy Tungsten Balls From TUNGSTEN MANLooking to elevate your engineering projects..

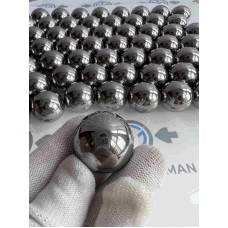

Carbide Balls Made by TUNGSTEN MAN: Grade K10-K40,Ground,High Precious ,Size :2.0mm-100mm

Carbide Balls Made by TUNGSTEN MAN: Grade K10-K40,Ground,High Precious ,Size :2.0mm-100mmWhen it com..

Carbide Plungers | High Pressure Pump Parts

Carbide Plungers | High-Pressure Pump Parts The size of the tungsten carbide plunger:For furthe..

Choosing the Right Tungsten Carbide Insert for Your Stabilizer

Choosing the Right Tungsten Carbide Insert for Your StabilizerLooking for the perfect tungsten carbi..

Dia 4.50″ , 5.00″ ,5.50″ ,5.75″ Tungsten Carbide Plunger

Dia 4.50″, 5.00″,5.50″,5.75″ Tungsten Carbide Plunger TUNGSTEN MAN is a manufacturer of Tungste..

Flow Control Carbide Points

How to Choose Quality Tungsten Carbide Points For Your Valve SystemChoosing the right tungsten carbi..

High Pressure Pump Carbide Plunger--TUNGSTEN MAN

High-Pressure Pump Carbide Plunger--TUNGSTEN MANThe Tolerance of Tungsten Carbide Plunger.Tolerance ..

How to Choose the Right PCD Substrate for Your PCD Cutter

How to Choose the Right PCD Substrate for Your PCD Cutter Choosing the right PCD substrate for ..

How to Choose the Right Tungsten Carbide Bushing for Your Applications.

How to Choose the Right Tungsten Carbide Bushing for Your Applications.Choosing the right tungsten c..

Milling Balls--Tungsten Carbide Balls

TUNGSTEN MAN's Tungsten Carbide Balls are Perfect Milling Balls for Optimal Grinding EfficiencyAre y..

OD 5/8" High-Pressure Pump Plungers For 40K UHP Pumps

OD 5/8" High-Pressure Pump Plungers For 40K UHP PumpsWhat is the high-pressure plunger pump?High-pre..

PDC Cutter

The Evolution of PDC Cutters: How TUNGSTEN MAN's PDC Cutters are Revolutionizing the Oil and Gas Ind..

Precision Tungsten Carbide Balls

Where to Buy Quality Tungsten Carbide Balls Online Looking for affordable and high-quality tung..

The Advantages of Using Tungsten Carbide Grinding Media in Ball Mills

The Advantages of Using Tungsten Carbide Grinding Media in Ball MillsTungsten carbide grinding media..

The Best Tungsten Carbide Bushings For Oil And Gas Industry

The Best Tungsten Carbide Bushings For the Oil And Gas Industry Made by TUNGSTEN MANLooking to enhan..

The Top Carbide Bushing Manufacturers in China--TUNGSTEN MAN

The Top Carbide Bushing Manufacturers in China--TUNGSTEN MANLooking for reliable carbide bushing man..

Tungsten Carbide Balls

Tungsten Carbide BallsIntroducing tungsten carbide balls: the unyielding force propelling precision ..

Tungsten Carbide Balls

Buy Tungsten Carbide Balls From TUNGSTEN MAN- Quality & Precision GuaranteedFind the perfect tun..