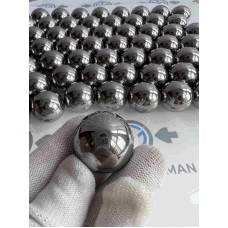

When it comes to precision and durability in industrial applications, tungsten carbide balls from TUNGSTEN MAN stand out as the go-to choice. Offering a comprehensive range of grades from K10 to K40, these high-precision ground carbide balls cater to various needs, whether for bearings, valves, or specialized machinery. Ranging in size from 2.0mm to an impressive 100mm, TUNGSTEN MAN’s carbide balls are designed to withstand high pressure and extreme conditions, making them an ideal solution for industries seeking reliability and performance. Explore the unparalleled combination of strength and precision that only TUNGSTEN MAN can deliver, and take your projects to the next level.

When it comes to precision and durability in industrial applications, tungsten carbide balls from TUNGSTEN MAN stand out as the go-to choice. Offering a comprehensive range of grades from K10 to K40, these high-precision ground carbide balls cater to various needs, whether for bearings, valves, or specialized machinery. Ranging in size from 2.0mm to an impressive 100mm, TUNGSTEN MAN’s carbide balls are designed to withstand high pressure and extreme conditions, making them an ideal solution for industries seeking reliability and performance. Explore the unparalleled combination of strength and precision that only TUNGSTEN MAN can deliver, and take your projects to the next level.

The creation of tungsten carbide balls begins with the careful selection of raw materials. The primary ingredients include tungsten metal powder and carbon, which are combined to form tungsten carbide powder. This powder is then mixed with a binder material, usually cobalt or nickel, to enhance the strength and durability of the final product. The mixture is subjected to a high-temperature sintering process, which compacts and solidifies the powder into a dense, hard mass. This sintered material is then processed to form spherical balls through a series of grinding and polishing steps, ensuring a precise and uniform shape.

The sintering process is crucial in determining the quality and properties of the tungsten carbide balls. During sintering, the material is heated to temperatures exceeding 1,400 degrees Celsius in a controlled atmosphere. This high-temperature environment causes the tungsten carbide particles to bond together, forming a solid, cohesive mass. The binder material, typically cobalt or nickel, melts and flows between the carbide particles, further enhancing the mechanical strength and toughness of the final product. The sintered carbide balls are then cooled and subjected to a series of mechanical operations to achieve the desired size and surface finish.

Grinding and polishing are essential steps in the manufacturing process of tungsten carbide balls. These processes ensure that the balls have a smooth, mirror-like surface and precise dimensions. The grinding process involves the use of abrasive wheels and specialized machinery to remove excess material and achieve the desired shape and size. Polishing, on the other hand, involves the use of finer abrasives and polishing compounds to achieve a high-quality surface finish. The final product is then inspected for quality and precision, ensuring that each tungsten carbide ball meets the stringent standards set by TUNGSTEN MAN.

Tungsten carbide balls are widely used in various industries due to their exceptional hardness, wear resistance, and durability. One of the primary applications of these balls is in the manufacturing of precision bearings. Bearings are essential components in many types of machinery, including automotive engines, aerospace equipment, and industrial machines. Tungsten carbide balls provide superior performance in these applications, as they can withstand high loads, high speeds, and harsh operating conditions without significant wear or deformation.

In the oil and gas industry, tungsten carbide balls are used in valve components and drilling tools. These balls are capable of withstanding the extreme pressures and abrasive environments encountered in oil and gas extraction. Their high hardness and resistance to corrosion make them ideal for use in downhole tools, valve seats, and other critical components. Additionally, tungsten carbide balls are used in flow control devices, where their precise dimensions and smooth surface ensure accurate and reliable operation.

The medical and dental industries also benefit from the use of tungsten carbide balls. In medical devices, these balls are used in precision instruments, surgical tools, and prosthetic joints. Their biocompatibility, combined with their mechanical properties, makes them suitable for use in the human body. In the dental industry, tungsten carbide balls are used in dental burrs and cutting tools, providing superior cutting performance and longevity. The versatility and reliability of tungsten carbide balls make them indispensable in a wide range of industrial applications.

One of the key distinctions between different types of tungsten carbide balls is whether they are ground or unground. Ground carbide balls undergo a series of grinding and polishing processes to achieve precise dimensions and a smooth, polished surface. This results in a high degree of accuracy and consistency, making ground carbide balls ideal for applications that require tight tolerances and high precision. Unground carbide balls, on the other hand, have a rougher surface and less precise dimensions, as they do not undergo the same level of finishing.

The choice between ground and unground carbide balls depends on the specific requirements of the application. Ground carbide balls are typically used in high-precision applications, such as bearings, where the smooth surface and precise dimensions are critical for optimal performance. The polished surface of ground carbide balls reduces friction and wear, leading to longer-lasting components and improved efficiency. In contrast, unground carbide balls are often used in applications where precision is less critical, and cost considerations take precedence.

Another important factor to consider is the cost of ground versus unground carbide balls. Ground carbide balls are generally more expensive due to the additional processing steps involved in achieving the desired surface finish and dimensional accuracy. However, the improved performance and longevity of ground carbide balls can offset the higher initial cost, making them a cost-effective choice in the long run. Unground carbide balls, while less expensive, may require more frequent replacement and maintenance, potentially leading to higher overall costs in certain applications.

Ensuring the quality and reliability of tungsten carbide balls is of paramount importance to TUNGSTEN MAN. The company adheres to stringent quality standards and certifications to guarantee that each product meets the highest levels of performance and durability. One of the key quality standards followed by TUNGSTEN MAN is the ISO 9001 certification, which sets out the criteria for a quality management system. This certification demonstrates the company's commitment to continuous improvement, customer satisfaction, and the consistent production of high-quality tungsten carbide balls.

In addition to ISO 9001, TUNGSTEN MAN also complies with other industry-specific standards and certifications. For example, the company follows the ASTM (American Society for Testing and Materials) standards for the production and testing of tungsten carbide materials. These standards provide guidelines for the composition, mechanical properties, and performance characteristics of tungsten carbide balls, ensuring that they meet the rigorous demands of various industrial applications. Compliance with these standards is essential for maintaining the reliability and consistency of TUNGSTEN MAN's products.

TUNGSTEN MAN also implements strict quality control measures throughout the manufacturing process to ensure that each tungsten carbide ball meets the specified requirements. This includes thorough inspection and testing at various stages of production, from raw material selection to final product evaluation. Advanced testing equipment and techniques, such as coordinate measuring machines (CMM) and hardness testers, are used to verify the dimensions, surface finish, and mechanical properties of the carbide balls. These quality control measures help to identify and address any potential issues, ensuring that only the highest quality products reach the customer.

Selecting the right tungsten carbide ball for your specific application is crucial for achieving optimal performance and longevity. When choosing a carbide ball, it is essential to consider factors such as the required grade, size, surface finish, and cost. TUNGSTEN MAN offers a wide range of grades from K10 to K40, each with distinct properties and performance characteristics. Understanding the specific requirements of your application will help you determine the most suitable grade for your needs.

The size of the carbide ball is another important consideration. TUNGSTEN MAN provides carbide balls in sizes ranging from 2.0mm to 100mm, allowing you to select the appropriate size for your application. The size of the ball can impact its performance, particularly in terms of load-bearing capacity and wear resistance. It is essential to choose a size that meets the demands of your application while ensuring compatibility with the surrounding components.

Finally, consider the surface finish and cost when selecting a carbide ball. Ground carbide balls offer superior precision and performance, making them ideal for high-precision applications. However, they come at a higher cost compared to unground carbide balls. Unground carbide balls, while less expensive, may be suitable for applications with less stringent precision requirements. By carefully evaluating these factors, you can choose the right tungsten carbide ball that meets your needs and delivers the best value for your investment.

Tungsten Balls Manufacturer

- Brand: Tungsten Man

- Product Code: TCB002111

- Availability: In Stock

Related Products

Tungsten Carbide Balls

Buy Tungsten Carbide Balls From TUNGSTEN MAN- Quality & Precision GuaranteedFind the perfect tun..

Flow Control Carbide Points

How to Choose Quality Tungsten Carbide Points For Your Valve SystemChoosing the right tungsten carbi..

Tungsten Carbide Sleeves For Flow Control In Oil&Gas Industry

Tungsten Carbide Sleeves For Flow Control In Oil&Gas Industry How to Select the Right Tungs..

What is YG8 tungsten carbide?

What is YG8 tungsten carbide?YG8 Tungsten Carbide: The Ideal Material for High-Performance ToolsYG8 ..

How to Choose the Right Tungsten Carbide Bushing for Your Applications.

How to Choose the Right Tungsten Carbide Bushing for Your Applications.Choosing the right tungsten c..

YG6 Carbide in Cutting Tools

YG6 Carbide in Cutting ToolsYG6 carbide is a high-performance material widely used in cutting tools...

YG10X Carbide: The Future of Cutting Tools

YG10X Carbide: The Future of Cutting ToolsDiscover the cutting-edge technology of YG10X carbide, the..

Carbide Circular Blade

Carbide Circular BladeThe Ultimate Guide to Choosing the Right Carbide Circular Blade for Cutting Pr..

Tungsten Carbide Metal

Tungsten Carbide Metal The Ultimate Guide to Tungsten Carbide Metal Manufacturer by TUNGSTEN MA..

Tungsten Carbide Bush

Tungsten Carbide BushApplication requirements: Understand the specific application for which you nee..

Tungsten Carbide Flanges

Tungsten Carbide FlangesThe Ultimate Guide to Tungsten Carbide Flanges Made by TUNGSTEN MANWel..

Milling Balls--Tungsten Carbide Balls

TUNGSTEN MAN's Tungsten Carbide Balls are Perfect Milling Balls for Optimal Grinding EfficiencyAre y..

What Is Tungsten Carbide ?

What Is Tungsten Carbide? The Ultimate Guide to Tungsten Carbide: Uncovering the Secrets of thi..

Tungsten Carbide Hardness

What is Tungsten Carbide Hardness?Understanding Tungsten Carbide Hardness: Everything You Need to Kn..

Understanding Tungsten Carbide: The Sturdy Material Revolutionizing Industries

Understanding Tungsten Carbide: The Sturdy Material Revolutionizing IndustriesWith its exceptional s..

The Best Tungsten Carbide Bushings For Oil And Gas Industry

The Best Tungsten Carbide Bushings For the Oil And Gas Industry Made by TUNGSTEN MANLooking to enhan..

Tungsten Carbide For Sale

Tungsten Carbide For SaleTungsten Carbide by TUNGSTEN MAN✅ 92.5-93.5 HRA Hardness - Outlas..

Tungsten Carbide Tubes: Sizes, Applications, and Tips for Choosing the Right One

Unveiling the Power of Tungsten Carbide Tubes: Sizes, Applications, and Tips for Choosing the Right ..

GT55 Carbide Cold Heading Dies

The Ultimate Guide to GT55 Carbide Cold Heading DiesIn the realm of high-performance industrial tool..

Tungsten Carbide: You Have To Know In 2026

Tungsten Carbide: You Have To Know In 2026 Discover why tungsten carbide from TUNGSTEN MAN is s..

Understanding Carbide Tungsten

Understanding Carbide Tungsten: Understanding Carbide Tungsten: Tungsten? Tungsten Carbid..

Tags: Price tungsten ball, tungsten ball for sale, p ool balls tungsten ball, t ungsten ball nearby, b lack tungsten b all, reviews tungsten ball, tungsten ball sal e, used tungsten ba ll, blue tungsten en b all, yellow tungs balls ball, buy tung gree grey all, gray to tungs ten ball, red tungsten ball, amazon tunst en ball, meaningballst en bal l, tungsten ball un der $2 50, size tung sten b all, large tun gsten ball, brand tungsten ball, ebay tu ngsten ball, online tu ngsten n ball,jig tu ngsten en ball,Walmart tungsten ball, tungsten ball,amazon.com tungsten ball, tungsten ball free shipping