Tungsten Carbide Blanks--End Mill Blanks

How to Select Quality End Mills Blanks for Maximum Performance

Get the most out of your end mills blanks with tips on selecting quality materials for maximum performance. Learn how to choose end mills blanks today!

Choosing the right end mill blanks to fit your needs is an essential part of getting the most out of any machining project. Read on for tips on how to select quality materials and maximize performance when using end mills blanks.

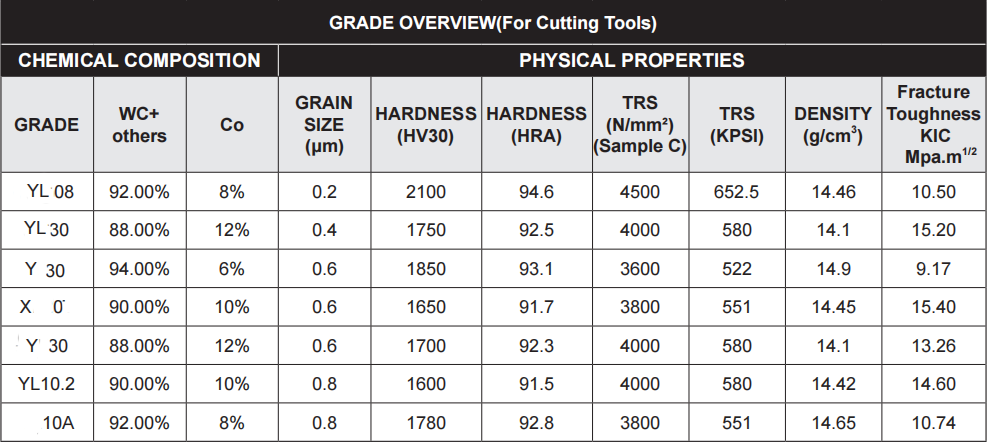

Select Tungsten Carbide Grade Appropriate for Your Application.

One of the most important considerations when selecting end mills to blank is the grade of tungsten carbide used. Different grades have different levels of hardness, abrasiveness, and durability, so you need to select the grade that best matches your application needs. Generally speaking, higher-grade tungsten carbide blanks are more expensive but offer better performance and longer tool life; however, lower-grade options may be suitable for applications with less demanding requirements.

Understand Different Types of End Mills and Their Benefits.

Knowing the different types of end mills and their benefits can help you decide which type is best for your application. The three main categories are corner radius, square-end, and ball-nose end mills. Corner radius end mills provide greater strength than sharp corners due to the rounded edges, while square-end end mills provide better chip evacuation and improved surface finish quality. Ball nose cutters have curved shapes that allow them to plunge deeper than other cuts, making them ideal for 3D machining applications.

Choose the Right Carbide Blank to Fit Your Requirements.

The carbide blank you choose must match the requirements of your specific application. Carbide materials vary significantly in hardness and wear resistance, with CBN (cubic boron nitride) being the hardest grade. If you’re not sure what grade of carbide is best for your application, talk to an expert who can help you make the right decision. Additionally, be sure to consider heat treatment requirements which vary depending on the complexity of the part geometry and application.

.jpg)

Consider Flute Length, Shape, and Geometry When Making Your Selection.

When selecting an end mill, it’s important to consider the flute length, shape, and geometry. The number of flutes will determine how quickly the tool will cut material as well as what type of finish you’ll get. The shape of the flute will determine chip evacuation, which is important for efficient cutting. Flute geometry also affects the way the cutting force is distributed along the cutting edge, which can influence tool life and cutter accuracy.

Evaluate the Comparative Prices of Quality End Mills Blanks to Get the Best Value for your Investment.

When selecting quality end mills blanks, it can be difficult to determine the best value among all the options. Price is an important consideration, but it’s equally important to look at features and benefits that offer better performance or reliability. You should also evaluate comparative prices whenever possible to make sure you’re getting the best value for your investment.

For further information (MOQ, price, delivery, etc), please request a quote or send us an email at info @ tungstenman.com Our sales team and engineers are ready to offer their expertise

Carbide Blanks--End Mill Blanks

- Brand: Tungsten Man

- Product Code: EMB005

- Availability: In Stock

Available Options

Related Products

Buy Tungsten Carbide Rods

Buy Tungsten Carbide Rods The TOP 1 thing you should know before you buy tungsten carbide rods ..

Tungsten Carbide Rods Suppliers

Tungsten Carbide Rods SuppliersAvailable size :Solid Tungsten Carbide Rods, diameter from 3mm to 30m..

Tungsten Carbide Tool Blanks--TUNGSTEN MAN

Tungsten Carbide Tool Blanks--TUNGSTEN MANAvailable size :Solid Tungsten Carbide Rods, diameter from..

Tungsten Carbide Rods For Sale - TUNGSTEN MAN

Tungsten Carbide Rods For Sale - TUNGSTEN MANTUNGSTEN MAN is a manufacturer of Tungsten carbide rods..

What is YG8 tungsten carbide?

What is YG8 tungsten carbide?YG8 Tungsten Carbide: The Ideal Material for High-Performance ToolsYG8 ..

YG6 Carbide in Cutting Tools

YG6 Carbide in Cutting ToolsYG6 carbide is a high-performance material widely used in cutting tools...

YG10X Carbide: The Future of Cutting Tools

YG10X Carbide: The Future of Cutting ToolsDiscover the cutting-edge technology of YG10X carbide, the..

Carbide Circular Blade

Carbide Circular BladeThe Ultimate Guide to Choosing the Right Carbide Circular Blade for Cutting Pr..

Tungsten Carbide Metal

Tungsten Carbide Metal The Ultimate Guide to Tungsten Carbide Metal Manufacturer by TUNGSTEN MA..

What Is Tungsten Carbide ?

What Is Tungsten Carbide? The Ultimate Guide to Tungsten Carbide: Uncovering the Secrets of thi..

Tungsten Carbide Hardness

What is Tungsten Carbide Hardness?Understanding Tungsten Carbide Hardness: Everything You Need to Kn..

Understanding Tungsten Carbide: The Sturdy Material Revolutionizing Industries

Understanding Tungsten Carbide: The Sturdy Material Revolutionizing IndustriesWith its exceptional s..

Tungsten Carbide For Sale

Tungsten Carbide For SaleTungsten Carbide by TUNGSTEN MAN✅ 92.5-93.5 HRA Hardness - Outlas..

Tungsten Carbide Tubes: Sizes, Applications, and Tips for Choosing the Right One

Unveiling the Power of Tungsten Carbide Tubes: Sizes, Applications, and Tips for Choosing the Right ..

GT55 Carbide Cold Heading Dies

The Ultimate Guide to GT55 Carbide Cold Heading DiesIn the realm of high-performance industrial tool..

Tungsten Carbide Rods

Tungsten Carbide Rods: Understanding Price Dynamics, Quality Consistency, and Manufacturer Excellenc..

Tungsten Carbide: You Have To Know In 2026

Tungsten Carbide: You Have To Know In 2026 Discover why tungsten carbide from TUNGSTEN MAN is s..

Understanding Carbide Tungsten

Understanding Carbide Tungsten: Understanding Carbide Tungsten: Tungsten? Tungsten Carbid..

Tags: carbide blanks, tungsten carbide blanks, round carbide blanks, carbide blanks suppliers, rectangular carbide blanks, carbide blanks round, carbide blanks flat, flat carbide blanks, square carbide blanks, carbide blanks for sale, how to cut carbide blanks, micro grain carbide blanks, Kennametal carbide blanks, c2 carbide blanks, stb carbide blanks, carbide blanks manufacturers, cemented carbide blanks, carbide blanks Canada, unground carbide blanks, solid carbide blanks

-228x228.jpg)