Tungsten Carbide Rods: Understanding Price Dynamics, Quality Consistency, and Manufacturer Excellence

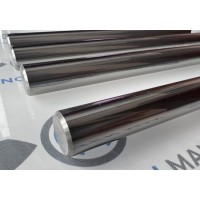

In the precision engineering and manufacturing sectors, tungsten carbide rods are indispensable for applications requiring extreme hardness, wear resistance, and dimensional stability. As a critical component in tools like drills, end mills, and dies, their performance directly impacts production efficiency. However, fluctuating tungsten prices and concerns about quality consistency often pose challenges for buyers. This article explores how tungsten prices affect carbide rod costs, why stable quality matters, and how partnering with a reliable manufacturer like TUNGSTEN MAN ensures optimal value and performance.

The Impact of Tungsten Prices on Carbide Rod Costs

Tungsten, the primary raw material in tungsten carbide (WC), accounts for over 90% of the alloy's composition. Its price is influenced by global supply-demand dynamics, mining regulations, and geopolitical factors. For example:

2023-2024 saw a 25% surge in tungsten prices due to supply chain disruptions in major producing regions like China and Vietnam.

Recycling initiatives help mitigate price volatility but cannot fully offset raw material cost fluctuations.

At TUNGSTEN MAN, we stabilise costs through:

Strategic Stockpiling: Maintaining a 6-month inventory of tungsten powder to buffer against short-term price spikes.

Vertical Integration: Owning the entire production chain—from powder metallurgy to final machining—reduces middleman markups.

Long-Term Supplier Contracts: Securing preferential pricing with certified tungsten ore suppliers through annual volume commitments.

Why Stable Quality is Non-Negotiable for Tungsten Carbide Rods

Inconsistent quality can lead to catastrophic tool failure, production downtime, and costly rework. Premium carbide rods must exhibit:

Uniform Microstructure: Fine-grain WC-Co alloys (grain size ≤1.0μm) for superior hardness (86-93 HRA) and transverse rupture strength (≥2,500 MPa).

Tight Dimensional Tolerances: Diameter accuracy within ±0.001mm (ISO h6) and straightness ≤0.05mm/m for precision applications like aerospace drilling.

Corrosion Resistance: Cobalt binder grades optimised for wet machining environments (e.g., WC-12Co for stainless steel processing).

TUNGSTEN MAN’s Quality Assurance Process:

ISO 9001:2015 Certified: Every batch undergoes metallographic analysis, ultrasonic testing, and hardness mapping.

Lot Traceability: Unique serial numbers for each rod lot, enabling full 追溯 from raw material to finished product.

Standard Grades, Sizes, and Customization Options

Popular Grades for Diverse Applications

When the Co content is 6% and the average grain size of WC is 0.4μm, the density of tungsten carbide rods is 14.5-14.7g/cm3, the bending strength is greater than or equal to 3500MPa, and the hardness is 94HRA (±0.5), suitable for powder metallurgy Processing and can be made into PCB (printed circuit board).

When the Co content is 8% and the average WC grain is 0.5μm, the density of the tungsten carbide rods is 14.4-14.6g/cm3, the bending strength is greater than or equal to 3600MPa, and the hardness is 93.3HRA (±0.5), suitable for hard ends Milling and fine milling, processing fibre, wood, plastic, brass, aluminium alloy, etc., can make PCB micro drills and carving knives.

When the Co content is 10% and the average grain size of WC is 0.8μm, the density of tungsten carbide rods is 14.35-14.5g/cm3, the bending strength is greater than or equal to 4000MPa, and the hardness is 91.7HRA (±0.5), which is suitable for processing cast iron. The first choice for aluminium alloy and various non-metallic materials; it is suitable for processing materials with a hardness lower than HRC55, and has good versatility.

When the Co content is 10% and the average WC grain size is 1.0μm, the density of tungsten carbide rods is 14.4-14.55g/cm3, the bending strength is greater than or equal to 3800MPa, and the hardness is 91.2HRA (±0.5), which can be used for ordinary end milling, Rough milling, suitable for HRC30-45 material processing.

When the Co content is 12% and the average grain size of WC is 0.4μm, the density of tungsten carbide rods is 13.95-14.25g/cm3, the bending strength is greater than or equal to 4000MPa, and the hardness is 92.5HRA (±0.5), suitable for processing grey cast iron, Titanium alloys, heat-resistant materials, stainless steel, hardened steel, glass fibre reinforced plastics and composite materials, suitable for high-speed processing.

When the Co content is 9% and the average grain size of WC is 0.2μm, the density of tungsten carbide rods is 14.2-14.4g/cm3, the bending strength is greater than or equal to 4000MPa, and the hardness is 93.7HRA (±0.5), which is suitable for processing high Strength, high wear resistance material.

When the Co content is 7% and the average grain size of WC is 0.5μm, the density of the tungsten carbide rods is 14.4-14.7g/cm3, the bending strength is greater than or equal to 3600MPa, and the hardness is 93.3HRA (±0.5), which is suitable for machine tools with relatively high rigidity. Good finishing can be made into a reamer, deep hole drill and PCB (printed circuit board)

When the Co content is 5% and the average grain size of WC is 0.4μm, the density of the tungsten carbide rods is 14.5-14.8g/cm3, the bending strength is greater than or equal to 3500MPa, and the hardness is 94HRA (±0.5), which has excellent wear resistance Sex, can be made into PCB.

When the Co content is 10% and the average grain size of WC is 0.5μm, the density of the tungsten carbide rods is 14.15-14.3g/cm3, the bending strength is greater than or equal to 4000MPa, and the hardness is 93.0HRA (±0.5), and the machinable hardness is in Materials between 45-65HRC can be used for milling high-temperature resistant steel, hardened steel, grey cast iron, heat-resistant alloy, titanium alloy, etc., suitable for high-speed processing.

When the Co content is 10% and the average grain size of WC is 0.6μm, the density of tungsten carbide rods is 14.4-14.55g/cm3, the bending strength is greater than or equal to 3800MPa, and the hardness is 92.1HRA (±0.5), suitable for machine tool rigidity It is better for processing stainless steel, aluminium alloy, grey cast iron, titanium alloy and glass fibre reinforced plastic.

Standard Sizes & Tolerances

Diameter Range: 0.5mm to 100mm (0.02" to 4")

Length Range: 5mm to 2,000mm (0.2" to 78.7")

Straightness: ≤0.03mm/m for diameters ≤10mm; ≤0.05mm/m for larger sizes

Surface Finish: Ra ≤0.2μm (ground rods); Ra ≤0.8μm (as-sintered rods)

Customization Capabilities

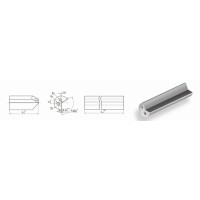

Need special tapers, threads, or coatings? We offer:

Precision Grinding: To IT5-IT6 tolerance standards

PVD Coatings: TiN, TiCN, or AlCrN for enhanced wear resistance

Custom Packaging: Anti-oxidation vacuum packing for long-term storage

Inventory & Lead Times: Reliability When You Need It

Stock Availability: Over 50,000 standard rods in stock (YG6, YG8, WC-10Co grades in 2-20mm diameters)

Lead Times:

Standard sizes: 7-15 days (global shipping)

Custom orders: 20-30 days (including material synthesis and machining)

Emergency Services: Rush production options with 5-day turnaround for critical orders

Why TUNGSTEN MAN Stands Out as Your Preferred Manufacturer

Decades of Expertise: 20+ years specializing in tungsten carbide products, serving over 3,000 industrial clients worldwide.

Cost Transparency: Detailed price breakdowns showing raw material, processing, and logistics costs—no hidden fees.

Technical Support: Free application engineering consultations to help select the right grade and dimensions for your project.

Sustainability Commitment: 100% recycled water in our manufacturing process and 95% waste recycling rate.

Ready to Source High-Quality Tungsten Carbide Rods?

Don’t let price volatility or quality risks disrupt your production. Partner with TUNGSTEN MAN for:

Stable pricing backed by strategic raw material management

ISO-certified quality that meets aerospace and medical device standards

Fast delivery from our global warehouses in the US, EU, and Asia

Samples order :

Solid Tungsten Carbide Rods are just one material, that needs to be processed and reused, so the problem can occur in this process or our rods.

Therefore, we strongly recommend that you purchase some samples for testing. This way you can very clear understanding of our material that is suitable for you. But also, you have previously purchased product comparison.

what are your questions about our Solid tungsten carbide rods?

For further information (MOQ, price, delivery, etc.), please request a quote or send an email to:[email protected]. Our sales team and engineers are ready to offer their expertise

Buy Tungsten Carbide Rods

- Product Code: STCR061

- Availability: In Stock

Available Options

Related Products

Carbide Rods

Tungsten Carbide Rods SuppliersNeed quality carbide rods for your industry? Check out the guide from..

Buy Tungsten Carbide Rods

Buy Tungsten Carbide Rods The TOP 1 thing you should know before you buy tungsten carbide rods ..

Factors To Consider When Choosing A Carbide Rod Manufacturer

Factors To Consider When Choosing A Carbide Rod ManufacturerCarbide rods find wide-ranging applicati..

Why TUNGSTEN MAN Is Your Best Tungsten Carbide Supplier

Why TUNGSTEN MAN Is Your Best Tungsten Carbide SupplierEnter TUNGSTEN MAN, the industry leader commi..

STB Rectangular Carbide Blanks For Cutting Tools Manufacturing

STB Rectangular Carbide Blanks For Cutting Tools ManufacturingIn the ever-evolving world of cutting ..

10 Facts You Must Know About Tungsten Carbide In 2025

10 Facts You Must Know About Tungsten Carbide In 2025What is so special about tungsten carbide?Tungs..

Hard Metal --10 Facts You Must Know About Tungsten Carbide In 2025

Hard Metal --10 Facts You Must Know About Tungsten Carbide In 2025In the year 2025, the hard metal t..

The facts of Tungsten Carbide: TUNGTEN MAN is a manufacturer telling trust.

The facts of Tungsten Carbide: TUNGTEN MAN is a manufacturer telling trust.Tungsten Carbide is a re..

Carbide Grade

K10, K20, K30 K40, Carbide Grade: How to Choose the Perfect Carbide Grade For Your Cutting ToolAre y..

ØD3.00mm Tungsten Carbide End Mill Blanks 12% Cobalt

ØD3.00mm Tungsten Carbide End Mill Blanks 12% Cobalt Tungsten Carbide End Mill Blanks Grade :Tu..

Carbide Blanks Suppliers--TUNGSTEN MAN

Leading Carbide Blanks Manufacturers for Businesses Worldwide--TUNGSTEN MANFind top-grade carbide bl..

ØD8.00mm Tungsten Carbide End Mill Blanks 12% Cobalt

ØD8.00mm Tungsten Carbide End Mill Blanks 12% Cobalt Tungsten Carbide End Mill Blanks Size..

The Ultimate Guide to Anti-Vibration Tool : Tungsten Boring Bar VS Tungsten Carbide Boring Bar

The Ultimate Guide to Anti-Vibration Tool: Tungsten Boring Bar VS Tungsten Carbide Boring BarAre you..

Carbide Rods: How To Choose Carbide Rods In 2025 ?

Carbide Rods: How To Choose Carbide Rods In 2025 ?Searching for the perfect carbide rods can be over..

what is solid carbide

What is Solid Carbide? Properties, Uses, and Benefits ExplainedDiscover what solid carbide is, how i..

The Guide to TUNGSTEN MAN's Carbide Blanks: Grade, Tolerance, Price, Lead time.

The Guide to TUNGSTEN MAN's Carbide Blanks: Grade, Tolerance, Price, Lead time.Unlock the unparallel..

Tungsten Carbide Rod--TUNGSTEN MAN

The Best Guide to Tungsten Carbide Rod in 2025: Everything You Need to KnowWelcome to the ultimate g..

Tungsten Carbide Rods Suppliers

Tungsten Carbide Rods SuppliersAvailable size :Solid Tungsten Carbide Rods, diameter from 3mm to 30m..

Tungsten Carbide Rods For Sale - TUNGSTEN MAN

Tungsten Carbide Rods For Sale - TUNGSTEN MANTUNGSTEN MAN is a manufacturer of Tungsten carbide rods..

Solid Carbide Rods - TUNGSTEN MAN

Solid Carbide Rods - TUNGSTEN MANAvailable size :Solid Tungsten Carbide Rods, diameter from 3mm to 3..

Carbide Rods: Everything You Need to Knon in 2025--TUNGSTEN MAN

Carbide Rods: Everything You Need to Know in 2025--TUNGSTEN MANWelcome to Tungsten Man, your ultimat..

Best Carbide Blanks Suppliers in China

The Best Carbide Blanks Suppliers in ChinaLooking for the best carbide blanks suppliers in China? We..

Carbide Rods Suppliers

Carbide Rods SuppliersWhere to Buy Quality Carbide Rods?Get affordable and reliable Carbide Rods fro..

Carbide Rod Manufacturers

Carbide Rod ManufacturersWhere to Find the Top Carbide Rod Manufacturers in 2024Ready to find the be..

Tungsten Carbide Blanks--End Mill Blanks

Tungsten Carbide Blanks--End Mill BlanksHow to Select Quality End Mills Blanks for Maximum Performan..

Best Tungsten Carbide Rod Blanks Manufacturer In China-TUNGSTEN MAN

Best Tungsten Carbide Rod Blanks Manufacturer In China-TUNGSTEN MANUnderstanding the Different Types..

Carbide Rod Supplier In China

TUNGSTEN MAN: Leading Suppliers of Carbide Rods from China Looking for reliable and high-qualit..

Carbide Rods As Sintered Length 330 (310) mm

Carbide Rods As Sintered Length 330 (310) mm Grade Of Tungsten Carbide Rods ..

Carbide Rods Ground To h6 Length 330 mm Chamfered 45°

Carbide Rods Ground To h6 Length 330 mm Chamfered 45° Grade Of Tungsten Carbide RodSizes Of Tungsten..

Carbide Rods Ground To h6 Length 100 mm Chamfered 45°

Carbide Rods Ground To h6 Length 100 mm Chamfered 45°Grade Of Tungsten Carbide RodGrade ..

Carbide Rods ,Cut To Length--Inches Sizes Chamfered

Carbide Rods, Cut To Length--Inches Sizes Chamfered Grade Of Tungsten Carbide RodGrade WC+other..

Carbide Rods ,Cut To Length Ground To h6 Chamfered 45°

Carbide Rods, Cut To Length Ground To h6 Chamfered 45° Grade Of Tungsten Carbide RodGrade WC+ot..

Unground Carbide Rods With One Straight Coolant Hole

Unground Carbide Rods With One Straight Coolant Hole Grade Of Tungsten Carbide RodGrade WC+othe..

Unground Carbide Rods With Two Straight Coolant Holes

Unground Carbide Rods With Two Straight Coolant Holes Grade Of Tungsten Carbide RodGrade WC+oth..

Ball Nose Rod h6 Ground

Ball Nose Rod h6 Ground Grade Of Tungsten Carbide RodGrade WC+others CoGrain Size (μm)Hard..

Gun Drill Blank

Gun Drill Blank Grade Of Tungsten Carbide RodGrade WC+others CoGrain Size (μm)Hardne..

Tungsten Carbide Flat Bars

Tungsten Carbide Flat Bars Grade Of Tungsten Carbide RodGrade WC+others CoGrain Size (μm)H..

Tungsten Carbide Ball Nose Blanks h6 Ground

Mastering Precision: The Power of Carbide Ballnose Endmill BlanksTungsten Carbide Ball Nose Blanks h..

How to Choose the Right Carbide Blanks for Your Application

How to Choose the Right Carbide Blanks for Your ApplicationCarbide blanks are an essential component..

Carbide Rod Blanks

How to Choose the Right Carbide Rod Blanks for Your ProjectCarbide rod blanks are an essential compo..

Tungsten Carbide Manufacturer

Tungsten Carbide Manufacturer5 Factors to Consider When Choosing a Tungsten Carbide ManufacturerLook..

Tungsten Carbide Supplier

Tungsten Carbide SupplierTungsten Carbide Supplier Comparison: Which Company Offers the Best Value?L..

Tungsten Carbide Tools: The Pros and Cons

Tungsten Carbide Tools: The Pros and ConsTungsten carbide tools are known for their durability and s..

Why TUNGSTEN MAN is The Leading Carbide Rods Manufacturer in China

Why TUNGSTEN MAN is The Leading Carbide Rods Manufacturer in China Looking for a reliable carbi..

How to Choose the Right Solid Carbide Rods for Your Cutting Tools

How to Choose the Right Solid Carbide Rods for Your Cutting Tools Choosing the right solid carb..

The Science Behind Tungsten Titanium Carbide: How It Works and Why It's So Strong

The Science Behind Tungsten Titanium Carbide: How It Works and Why It's So StrongTungsten titanium c..

How to Buy Tungsten Carbide Strips: Size 1/8" x 1-1/4" x 6", K20, K30, K40, ground or unground.

How to Buy Tungsten Carbide Strips: Size 1/8" x 1-1/4" x 6", K20, K30, K40, ground or unground.Looki..

How Carbide Strips Improve Cutting Efficiency in Metalworking

How Carbide Strips Improve Cutting Efficiency in MetalworkingDiscover how carbide strips can revolut..

Choosing the Right Carbide Boring Bar for Your Machining Needs

Choosing the Right Carbide Boring Bar for Your Machining NeedsFind the perfect carbide boring bar fo..

Ground Tungsten Carbide Rods

Ground Tungsten Carbide RodsThe Science Behind Ground Tungsten Carbide Rods: How They Enhance Perfor..

TUNGSTEN MAN--Top manufacturer of Carbide Strips in Industrial Applications

TUNGSTEN MAN--Top manufacturer of Carbide Strips in Industrial ApplicationsTUNGSTEN MAN is the leadi..

How Carbide Rod Blanks Made ? Carbide Rod Banks Manufactured by TUNGSTEN MAN

How Carbide Rod Blanks Made? Carbide Rod Banks Manufactured by TUNGSTEN MANWelcome to Tungsten Man, ..

Carbide Wear Strips

Carbide Wear StripsCarbide wear strips are becoming increasingly popular in industries that demand r..

Carbide Rods Manufacture of High-Performance Carbide Rods And Affordable Price--TUNGSTEN MAN

Discover the Carbide Rods Manufacture of High-Performance Carbide Rods And Affordable Price--TUNGSTE..

Carbide Rods For PCB Tools

Carbide Rods For PCB Tools Grade Of Carbide Rods For PCB ToolsGrade WC+others CoGra..

How To Choose Tungsten Carbide Bars: Grade,Tolerance,sizes , Delivery Time ,

How To Choose Tungsten Carbide Bars: Grade, Tolerance, sizes, Delivery Time When it comes to se..

Gun Drill Blank With Kidney Holes

Gun Drill Blank With Kidney Holes Grade Of Gun Drill Blank With Kidney HolesGrade WC+others&nbs..

Carbide Rod Prices in 2024: A Comprehensive Overview for Buyers

Carbide Rod Prices in 2024: A Comprehensive Overview for BuyersIn 2024, the carbide rod market is ex..

Carbide Rods With Coolant Hole

Carbide Rods With Coolant HoleMaximizing Efficiency in Deep Hole Drilling: Why TUNGSTENMAN's Carbide..

Tungsten Carbide Bars

Tungsten Carbide Bars: Best Materials for Your Cutting Tools Are you in search of the best mate..

Tags: tungsten carbide rods, tungsten price effect on carbide rod price, stable quality tungsten carbide rods manufacturer, tungsten carbide rod grades, carbide rod dimensions, tungsten carbide rod tolerance, fast delivery tungsten carbide rods, tungsten carbide rod inventory

length rods-200x200.jpg)

Rod-200x200.jpg)

-200x200.jpg)

-200x200.jpg)

-200x200.jpg)