STB Rectangular Carbide Blanks For Cutting Tools Manufacturing

In the ever-evolving world of cutting tools manufacturing, STB rectangular carbide blanks stand out as a game-changer. Renowned for their exceptional hardness and durability, TUNGSTEN MAN offer carbide blanks that are pivotal in enhancing the precision and efficiency of various cutting processes. Whether you're engaged in metalworking, machining, or fabrication, the quality of your cutting tools directly impacts your production output.

Key Properties of STB Rectangular Carbide Blanks

STB rectangular carbide blanks are known for their impressive properties that make them ideal for cutting tools manufacturing. One of their most notable attributes is their exceptional hardness. Tungsten carbide, which is a primary component of these blanks, is one of the hardest materials available, second only to diamond. This hardness allows the carbide blanks to maintain a sharp cutting edge for an extended period, reducing the frequency of tool changes and increasing overall productivity.

In addition to their hardness, STB rectangular carbide blanks exhibit remarkable wear resistance. This property is crucial in cutting tools as it ensures that the tool remains effective even after prolonged use. The wear resistance is a result of the carbide's microstructure, which is composed of fine carbide grains that are uniformly distributed throughout the material. This uniform distribution helps in evenly distributing the stress during cutting operations, thereby enhancing the tool's lifespan.

Another key property of STB rectangular carbide blanks is their high thermal conductivity. During cutting operations, a significant amount of heat is generated, which can affect the tool's performance and the quality of the cut. The high thermal conductivity of carbide blanks helps in dissipating this heat efficiently, preventing the tool from overheating and ensuring consistent performance. This property is particularly beneficial in high-speed machining operations where temperature control is critical.

Types of Carbide Blanks and Their Applications

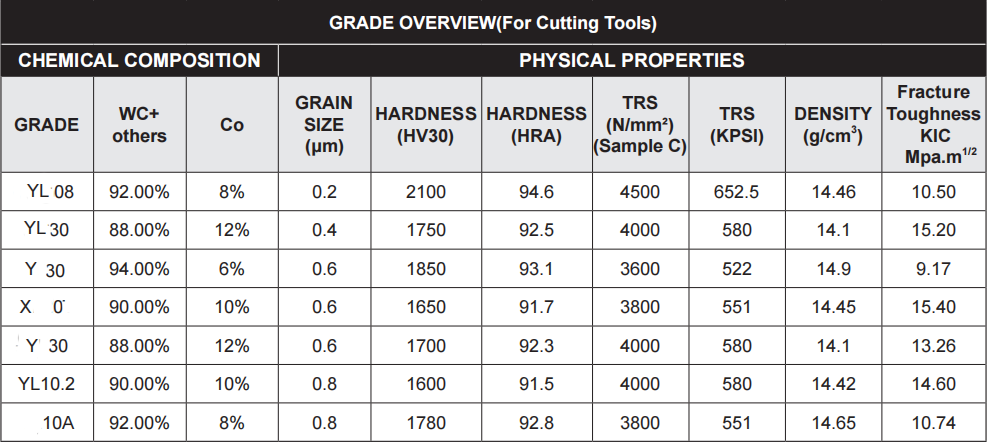

Carbide blanks come in various shapes and sizes, each designed for specific applications. STB rectangular carbide blanks are particularly popular due to their versatility and ease of use in different cutting tools. These blanks can be further categorised based on their composition and grain size, which affect their performance characteristics.

One common type of carbide blank is the fine-grain carbide blank. These blanks are made from carbide particles that are less than one micron in size. The fine-grain structure provides excellent hardness and wear resistance, making them suitable for high-precision cutting tools. They are often used in applications that require fine finishes, such as in the manufacturing of precision moulds and dies.

Another type of carbide blank is the coarse-grain carbide blank. These blanks have larger carbide particles, typically ranging from one to six microns. Coarse-grain carbide blanks offer good toughness and are less prone to chipping, making them ideal for heavy-duty cutting applications. They are commonly used in the production of tools for rough machining, drilling, and mining operations where durability is essential.

In addition to fine and coarse-grain carbide blanks, there are also mixed-grain carbide blanks that combine the properties of both. These blanks offer a balance between hardness and toughness, making them suitable for a wide range of cutting applications. Mixed-grain carbide blanks are often used in the manufacturing of general-purpose cutting tools that require a combination of precision and durability.

The Importance of Carbide Blanks in Cutting Tools

Carbide blanks play a critical role in the performance and longevity of cutting tools. The quality of the carbide blank directly impacts the tool's ability to cut efficiently and accurately. High-quality carbide blanks, such as STB rectangular carbide blanks, ensure that the cutting edge remains sharp and effective, leading to better production outcomes.

One of the primary reasons for the importance of carbide blanks in cutting tools is their ability to withstand high cutting forces. During machining operations, cutting tools are subjected to significant forces that can cause deformation and wear. Carbide blanks, with their superior hardness and wear resistance, can endure these forces without losing their cutting edge, ensuring consistent performance.

Furthermore, carbide blanks contribute to the overall cost-effectiveness of cutting tools. Although carbide blanks are more expensive than other materials such as high-speed steel, their durability and longevity justify the initial investment. With carbide blanks, manufacturers can reduce downtime caused by frequent tool changes and maintenance, leading to increased productivity and lower operational costs.

In addition to their mechanical properties, carbide blanks also offer chemical stability. They are resistant to corrosion and oxidation, which can degrade the tool's performance over time. This resistance ensures that the cutting tools remain effective even in harsh working environments, such as those involving high temperatures and aggressive chemicals.

Advantages of Using STB Rectangular Carbide Blanks

One of the significant advantages of using STB rectangular carbide blanks is their exceptional precision. These blanks are manufactured to exacting standards, ensuring uniformity in size and shape. This precision is crucial in the production of cutting tools, as it allows for the creation of tools with consistent dimensions and cutting edges. As a result, manufacturers can achieve higher accuracy in their machining operations, leading to better quality products.

Another advantage of STB rectangular carbide blanks is their versatility. These blanks can be used to produce a wide range of cutting tools, including end mills, drill bits, inserts, and reamers. The versatility of carbide blanks allows manufacturers to streamline their tool production processes, reducing the need for multiple types of raw materials. This simplification can lead to more efficient manufacturing operations and cost savings.

STB rectangular carbide blanks also offer excellent toughness, which is crucial for cutting tools used in demanding applications. The toughness of the carbide blanks prevents chipping and breakage, even under high-stress conditions. This property is particularly beneficial in applications such as heavy-duty machining and metal cutting, where tools are subjected to significant forces and impacts.

Additionally, the use of STB rectangular carbide blanks can improve the overall efficiency of cutting processes. The high hardness and wear resistance of the carbide blanks allow for faster cutting speeds and longer tool life. This efficiency translates to reduced machining times and increased production output. For manufacturers, this means the ability to meet tight deadlines and fulfil customer orders more effectively.

Future Trends in Carbide Blanks for Cutting Tools

The future of carbide blanks for cutting tools is poised for exciting developments, driven by advancements in materials science and manufacturing technologies. One of the emerging trends is the use of nanostructured carbide materials. These materials feature ultra-fine carbide grains, typically less than 100 nanometers in size. The nanostructured carbide offers superior hardness and toughness compared to traditional carbide materials, making it ideal for high-performance cutting tools.

Another trend in the carbide blanks industry is the integration of advanced coatings. Coatings such as titanium nitride (TiN) and diamond-like carbon (DLC) can enhance the performance of carbide blanks by providing additional wear resistance and reducing friction. These coatings can extend the tool life and improve the quality of the cut, making them valuable additions to cutting tools used in precision machining and high-speed operations.

Additive manufacturing, also known as 3D printing, is another area that holds promise for the future of carbide blanks. Advances in additive manufacturing technologies have made it possible to produce complex geometries and custom shapes with high precision. This capability can be leveraged to create carbide blanks with optimised designs that enhance cutting performance and reduce material waste. As 3D printing technology continues to evolve, it is expected to play a significant role in the production of high-quality carbide blanks.

Moreover, sustainability is becoming an increasingly important consideration in the manufacturing industry. There is a growing focus on developing eco-friendly carbide blanks that minimise environmental impact. This includes the use of recycled materials and the implementation of energy-efficient manufacturing processes. As manufacturers strive to meet sustainability goals, the demand for environmentally friendly carbide blanks is likely to rise.

Conclusion and Recommendations for Manufacturers

In conclusion, STB rectangular carbide blanks are a vital component in the cutting tools manufacturing industry. Their exceptional hardness, wear resistance, and thermal conductivity make them ideal for a wide range of cutting applications. The precision and versatility of these blanks contribute to improved machining accuracy and efficiency, leading to better production outcomes.

Manufacturers looking to enhance their cutting tools should consider the benefits of using STB rectangular carbide blanks. These blanks offer a cost-effective solution by reducing downtime and maintenance costs, while also providing superior performance and durability. By investing in high-quality carbide blanks, manufacturers can achieve higher productivity and better quality products.

As the industry continues to evolve, staying abreast of future trends in carbide blanks is essential. The adoption of nanostructured carbide materials, advanced coatings, and additive manufacturing technologies can further enhance the performance of cutting tools. Additionally, embracing sustainability practices can help manufacturers meet environmental goals and appeal to eco-conscious customers.

Overall, the use of STB rectangular carbide blanks represents a significant advancement in cutting tools. By leveraging the unique properties of these blanks, manufacturers can achieve greater precision, efficiency, and durability in their cutting operations. As a result, they can remain competitive in the market and continue to deliver high-quality products to their customers.

For further information (MOQ, price, delivery, etc), please request a quote or send us an email at [email protected]. Our sales team and engineers are ready to offer their expertise

Rectangular Carbide Blanks

- Brand: Tungsten Man

- Product Code: EMB0051

- Availability: In Stock

Available Options

Related Products

Buy Tungsten Carbide Rods

Buy Tungsten Carbide Rods The TOP 1 thing you should know before you buy tungsten carbide rods ..

Tungsten Carbide Rods Suppliers

Tungsten Carbide Rods SuppliersAvailable size :Solid Tungsten Carbide Rods, diameter from 3mm to 30m..

Tungsten Carbide Rods For Sale - TUNGSTEN MAN

Tungsten Carbide Rods For Sale - TUNGSTEN MANTUNGSTEN MAN is a manufacturer of Tungsten carbide rods..

What is YG8 tungsten carbide?

What is YG8 tungsten carbide?YG8 Tungsten Carbide: The Ideal Material for High-Performance ToolsYG8 ..

YG6 Carbide in Cutting Tools

YG6 Carbide in Cutting ToolsYG6 carbide is a high-performance material widely used in cutting tools...

YG10X Carbide: The Future of Cutting Tools

YG10X Carbide: The Future of Cutting ToolsDiscover the cutting-edge technology of YG10X carbide, the..

Carbide Circular Blade

Carbide Circular BladeThe Ultimate Guide to Choosing the Right Carbide Circular Blade for Cutting Pr..

Tungsten Carbide Metal

Tungsten Carbide Metal The Ultimate Guide to Tungsten Carbide Metal Manufacturer by TUNGSTEN MA..

What Is Tungsten Carbide ?

What Is Tungsten Carbide? The Ultimate Guide to Tungsten Carbide: Uncovering the Secrets of thi..

Tungsten Carbide Hardness

What is Tungsten Carbide Hardness?Understanding Tungsten Carbide Hardness: Everything You Need to Kn..

Understanding Tungsten Carbide: The Sturdy Material Revolutionizing Industries

Understanding Tungsten Carbide: The Sturdy Material Revolutionizing IndustriesWith its exceptional s..

Tungsten Carbide For Sale

Tungsten Carbide For SaleTungsten Carbide by TUNGSTEN MAN✅ 92.5-93.5 HRA Hardness - Outlas..

Tungsten Carbide Tubes: Sizes, Applications, and Tips for Choosing the Right One

Unveiling the Power of Tungsten Carbide Tubes: Sizes, Applications, and Tips for Choosing the Right ..

GT55 Carbide Cold Heading Dies

The Ultimate Guide to GT55 Carbide Cold Heading DiesIn the realm of high-performance industrial tool..

Tungsten Carbide Rods

Tungsten Carbide Rods: Understanding Price Dynamics, Quality Consistency, and Manufacturer Excellenc..

Tags: Rectangular Carbide Blanks, tungsten rectangular carbide blanks, rectangular carbide blanks for sale, tungsten carbide blank, carbide insert blanks, carbide raw material